What measures ensure safety during Flexible printed circuit manufacturers?

safety during Flexible printed circuit manufacturers

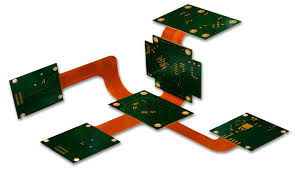

Ensuring safety during flexible printed circuit (FPC) manufacturing is paramount to protect both workers and the integrity of the final products. The production process involves various materials, chemicals, and equipment that can pose potential hazards if not handled properly. Implementing comprehensive safety measures is essential to mitigate risks and create a safe working environment in FPC manufacturing facilities.

One of the fundamental safety measures in flexible printed circuit manufacturers is providing appropriate personal protective equipment (PPE) to workers. This includes items such as gloves, safety glasses, lab coats, and face masks to protect against chemical exposure, burns, and other occupational hazards. Workers should receive training on the proper use of PPE and adhere to safety protocols at all times to minimize the risk of accidents and injuries.

Furthermore, proper ventilation systems are essential to control exposure to hazardous fumes and chemicals during the manufacturing process. FPC manufacturing may involve the use of soldering fluxes, adhesives, and cleaning solvents that emit volatile organic compounds (VOCs) and other harmful substances. Installing adequate ventilation systems, such as fume hoods and exhaust fans, helps remove airborne contaminants and maintain air quality within safe limits.

What measures ensure safety during Flexible printed circuit manufacturers?

Additionally, handling and disposal of hazardous materials and waste should be managed in accordance with relevant regulations and best practices. This includes proper storage of chemicals in designated areas, labeling of containers, and implementing procedures for spill containment and cleanup. Workers should receive training on the safe handling and disposal of hazardous materials to prevent environmental contamination and health risks.

Machine safety is another critical aspect of ensuring safety in FPC manufacturing facilities. Automated machinery used in the production process, such as soldering equipment, stencil printers, and pick-and-place machines, can pose risks of entanglement, crushing, and electrical hazards if not operated correctly. Implementing machine guarding, safety interlocks, and emergency stop mechanisms helps prevent accidents and injuries while maintaining productivity.

Moreover, regular maintenance and inspection of equipment are essential to identify and address potential safety hazards before they escalate. Routine checks of electrical systems, machinery, and safety devices help ensure that equipment is functioning properly and meets safety standards. Any defects or malfunctions should be promptly repaired or replaced to prevent accidents and downtime.

Fire safety is also a critical concern in FPC manufacturing facilities due to the use of flammable materials such as solder paste, adhesives, and cleaning solvents. Implementing fire prevention measures, such as proper storage of flammable materials, installation of fire detection and suppression systems, and conducting regular fire drills, helps reduce the risk of fire-related incidents. Workers should be trained in fire safety procedures and evacuation protocols to respond effectively in case of emergencies.

Furthermore, ergonomic considerations are important to prevent musculoskeletal injuries and promote worker well-being in FPC manufacturing. Tasks that involve repetitive motions, awkward postures, or heavy lifting can lead to strains, sprains, and other ergonomic injuries. Implementing ergonomic workstations, providing adjustable seating and tools, and offering training on proper lifting techniques help minimize the risk of injuries and improve overall workplace safety.

In conclusion, ensuring safety during flexible printed circuit manufacturing requires a comprehensive approach that addresses various hazards and risks inherent in the production process. By implementing measures such as providing PPE, maintaining proper ventilation, ensuring machine safety, managing hazardous materials, and promoting ergonomic practices, manufacturers can create a safe and healthy work environment for their employees while maintaining the quality and integrity of the products. Compliance with safety regulations and continuous improvement efforts are essential to mitigate risks and prevent accidents in FPC manufacturing facilities.