What are the environmental considerations for custom pcb?

environmental considerations for custom pcb

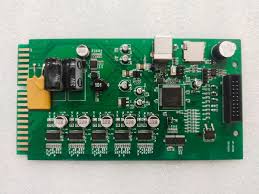

Environmental considerations are crucial in the design, manufacturing, use, and disposal of custom printed circuit boards (PCBs). As electronic devices become more pervasive in daily life, understanding and addressing the environmental impact of PCBs is essential for sustainability and responsible stewardship of natural resources.

One significant environmental consideration for custom PCBs is the selection of materials. PCBs typically contain a variety of materials, including fiberglass epoxy resin, copper, and solder. Choosing materials that are non-toxic, recyclable, and sourced sustainably helps minimize the environmental footprint of PCB manufacturing. Additionally, selecting materials with low environmental impact throughout the PCB’s lifecycle—from production to disposal—contributes to overall sustainability efforts.

The manufacturing process of custom pcb also has environmental implications. PCB fabrication involves several steps, including etching, drilling, and soldering, all of which can generate waste and emissions. Implementing environmentally friendly manufacturing practices, such as water-based cleaning solutions, energy-efficient equipment, and waste reduction strategies, helps minimize the environmental impact of PCB production. Furthermore, adhering to regulatory standards and certifications, such as ISO 14001 for environmental management systems, ensures compliance with environmental regulations and promotes responsible manufacturing practices.

What are the environmental considerations for custom pcb?

Energy consumption is another important environmental consideration for custom PCBs. The production and use of electronic devices, including PCBs, contribute to energy consumption and greenhouse gas emissions. Designing energy-efficient PCBs that minimize power consumption during operation helps reduce the environmental footprint of electronic devices. Additionally, implementing energy-saving features such as sleep modes and power management systems further enhances energy efficiency and sustainability.

End-of-life disposal presents significant environmental challenges for custom PCBs. Electronic waste, or e-waste, is a growing concern worldwide due to its toxic components and improper disposal practices. PCBs contain materials such as lead, mercury, and brominated flame retardants, which can leach into the environment if not disposed of properly. Recycling PCBs through certified e-waste recycling facilities helps recover valuable materials and reduces the need for virgin resources. Furthermore, designing PCBs for disassembly and recycling, such as using modular components and minimizing adhesives, facilitates the recycling process and promotes circular economy principles.

The environmental impact of custom PCBs extends beyond manufacturing and disposal to include their use phase. PCBs are integral components in electronic devices that consume energy and resources throughout their lifecycle. Optimizing the design of custom PCBs for energy efficiency, longevity, and recyclability helps minimize their environmental impact during use. Additionally, promoting sustainable practices such as repair and refurbishment extends the lifespan of electronic devices and reduces the need for new PCBs, further conserving resources and reducing waste.

Environmental regulations and standards play a critical role in shaping the environmental considerations for custom PCBs. Regulatory frameworks such as the European Union’s Restriction of Hazardous Substances (RoHS) directive and the Waste Electrical and Electronic Equipment (WEEE) directive set limits on the use of hazardous substances in electronics and establish requirements for e-waste management. Compliance with these regulations ensures that custom PCBs meet environmental standards and contribute to sustainable development goals.

In conclusion, environmental considerations are integral to the design, manufacturing, use, and disposal of custom PCBs. By selecting environmentally friendly materials, implementing sustainable manufacturing practices, designing for energy efficiency and recyclability, and adhering to regulatory standards, custom PCBs can minimize their environmental impact and contribute to a more sustainable future. By prioritizing environmental sustainability, the electronics industry can mitigate its environmental footprint and promote responsible stewardship of natural resources for generations to come.