How does Pcb assembly companies differ from PCB fabrication?

Pcb assembly companies differ from PCB fabrication

PCB assembly companies and PCB fabrication are two distinct but closely related processes within the realm of electronics manufacturing. While both are integral to the production of printed circuit boards (PCBs), they serve different purposes and involve different stages of the manufacturing process. Understanding the differences between PCB assembly companies and PCB fabrication sheds light on the complexity and specialization within the electronics industry.

pcb assembly companies fabrication is the initial stage of the manufacturing process, where raw materials are transformed into finished PCBs. This process begins with the creation of the PCB layout, which defines the placement of conductive traces, vias, pads, and other features on the board. The layout is then transferred onto a substrate material, typically fiberglass-reinforced epoxy laminate, using techniques such as etching or printing.

One of the key differences between PCB fabrication and assembly lies in the focus of each process. PCB fabrication primarily deals with the creation of the bare PCB, focusing on the fabrication of the substrate material and the deposition of conductive layers. Fabrication involves precise machining, drilling, and chemical processes to create intricate patterns and features on the board, ensuring that it meets the required specifications and tolerances.

How does Pcb assembly companies differ from PCB fabrication?

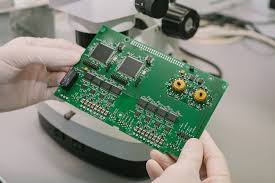

In contrast, PCB assembly companies specialize in the assembly of electronic components onto the fabricated PCBs to create functional electronic circuits. This process involves mounting components, such as resistors, capacitors, integrated circuits, and connectors, onto the PCB according to the layout provided. Assembly companies utilize advanced machinery and techniques to automate component placement and soldering, ensuring accuracy and consistency.

Another difference between PCB fabrication and assembly lies in the complexity of the processes involved. PCB fabrication requires specialized equipment and expertise to produce the intricate patterns and features required for modern electronic devices. Fabrication involves multiple steps, including substrate preparation, layer deposition, imaging, etching, drilling, and surface finishing, each of which must be executed with precision.

PCB assembly, on the other hand, focuses on the integration of electronic components onto the fabricated PCBs. While assembly also requires precision and attention to detail, it generally involves fewer steps than fabrication. Assembly companies must ensure that components are correctly positioned, soldered, and inspected to meet the required quality standards, but the process is more streamlined compared to fabrication.

Furthermore, PCB assembly companies often provide additional services beyond the assembly process itself. These services may include design for manufacturability (DFM) and design for assembly (DFA) consultation, prototyping, testing, and quality assurance. By offering comprehensive solutions, assembly companies help clients optimize the efficiency and cost-effectiveness of the manufacturing process.

In summary, PCB assembly companies and PCB fabrication represent distinct but interconnected stages of the electronics manufacturing process. PCB fabrication involves the creation of bare PCBs through processes such as substrate preparation, layer deposition, and etching, while PCB assembly focuses on the integration of electronic components onto fabricated PCBs to create functional circuits. Understanding the differences between these processes is essential for navigating the complexities of electronics manufacturing and delivering high-quality products to market.